Inventory management

Home » Inventory Management Guide

Successful inventory management is critical for every business that deals in physical goods, and touches on multiple parts of an operation – from the warehouse to the CEO’s office. In this inventory management guide we look at:

- Inventory management definitions and terminology

- The main inventory management formulas

- The best inventory software tools

- The main inventory management methods and practices

Inventory management definition

Inventory management is the practice of controlling the flow of goods and materials through a business, striking a balance between ensuring enough stock is available to fulfil customer orders, while minimising the costs of holding excess inventory.

What is inventory management?

While the definition is simple, in practice inventory management is a broad-ranging discipline. Often referred to as stock management, it determines how you track and control your business’ inventory as it is bought, manufactured, stored, and sold. Good inventory management oversees the entire flow of goods – from purchasing right through to sale – ensuring you always have the right quantities of the right item in the right location at the right time.

- Watch the next video: How The Unleashed Inventory Management System Works

- See the software in action: Unleashed Webinars

How does inventory management work?

Inventory management works by tracking products, components and ingredients across suppliers, stock on hand, production and sales to ensure that stock is used as efficiently and effectively as possible. It can go as deep as you need it to: for example, by examining the difference between dependent and independent demand, or forecasting sales to plan ahead. But at the end of the day, it all goes back to your stock.

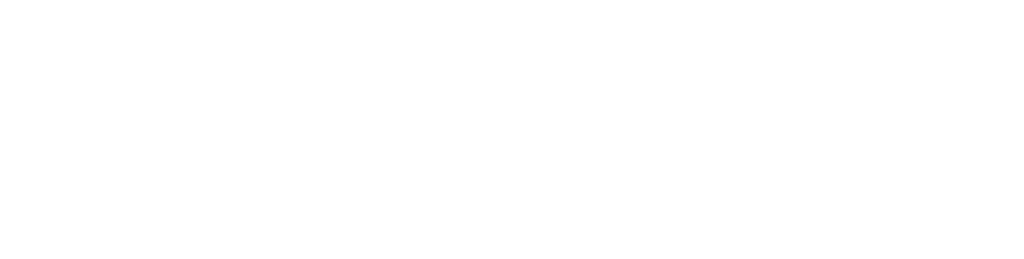

Inventory management example: Sam’s chairs

Sam decides to set up a business selling her handcrafted dining chairs. Each chair she makes requires 6 different sizes of wood, plus a cushion. She goes to her supplier and buys 10 planks of each size of wood she needs, plus 10 cushions. These are all now included in her business’ inventory.

As she turns raw materials into chairs, then sells them, Sam’s inventory levels will change. She’ll need to keep track how much of each material she has at any one time, how many chairs she can make, how fast she can make them, where her materials are, how many chairs she is selling and much more. This is all inventory management.

Don’t worry if that seems daunting — inventory management is much easier to digest once you break it down into the 5 key stages that your goods will go through.

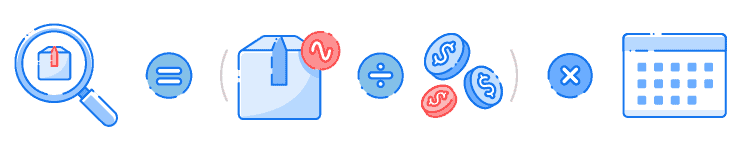

Inventory management process:

5 key stages

The inventory management process involves tracking and controlling stock as it moves from your suppliers to your warehouse to your customers. There are five main stages to follow:

- Purchasing: This can mean buying raw materials to turn into products, or buying products to sell on with no assembly required

- Production: Making your finished product from its constituent parts. Not every company will get involved in manufacturing — wholesalers, for instance, might skip this step entirely

- Holding stock: Storing your raw materials before they’re manufactured (if required), and your finished goods before they’re sold

- Sales: Getting your stock into customers’ hands, and taking payment

- Reporting: Businesses need to know how much it is selling, and how much money it makes on each sale

Continuing with our example from earlier, here’s how Sam’s company utilizes each stage of the process:

Inventory management vs inventory control

While they may sound similar, inventory control is a key part of inventory management, but it isn’t the same thing.

What is inventory control?

Inventory control is how you manage the stock you currently have in storage. This involves knowing your stock inside and out — how much is available, where it is and what condition it is in. It’s also about ensuring that you are storing stock efficiently, keeping inventory costs down and minimising the time spent counting and controlling inventory.

Learn more about inventory control.

Which comes first — management or control?

Inventory management is much broader than control: it takes your supply chain, manufacturing, fulfilment, sales and reporting into account. Almost any business will have to get an inventory management system in place before they drill down to control. Otherwise, you’ll have no way of managing suppliers, production or sales.

After that, there are countless methods for storing and selling your products better. Whether you focus on optimising purchasing, control, production or sales is up to you. You might, for instance, want to plan improvements based on previous operating experience — say, by changing how you count stock. Or you might want to tweak processes to reflect product and order profile changes, customer gains and losses or shifts in demand.

Periodic inventory management

Periodic inventory management is an inventory and accounting methodology where inventory and its value are measured at set intervals.

In periodic inventory management staff physically count every item in stock at the end of a set time period – often quarterly or annually. This provides an ending inventory balance, which can be compared to the starting balance to calculate an average inventory figure. This can be used in conjunction with inventory accounting metrics such as Cost of Goods Sold (COGS) to calculate figures such as the inventory turnover ratio.

Periodic inventory management challenges

Periodic inventory management is time- and labour-intensive. Because it requires a physical hand-count of products, it can only be done at semi-regular intervals given the staff cost and time required.

Additionally, as a periodic count can only be performed at intervals, the data it produces is less granular than data from perpetual inventory management.

Larger and more sophisticated organisations tend not to use periodic inventory management.

Perpetual inventory management

Perpetual inventory management is an inventory and accounting methodology where inventory and its value are measured continuously.

Using tools such as barcode scanners, inventory management software, digital point of sale (POS) systems and eCommerce software, inventory can be tracked as it passes through a business, automatically updating the system as required.

In perpetual inventory systems the number (or volume) of goods – known as Stock on Hand (SOH) is tracked in near-real time. And because purchase prices and sales prices – as well as variable costs such as freight and labour – can all be recorded digitally on purchase orders, sales orders and invoices, or via other digital transactions records – stock on hand values are also updated live.

In perpetual inventory management COGS is often calculated according to the average landed cost methodology, which takes a weighted average of the different prices paid for goods to calculate their value.

- Read more about COGS and inventory valuation methodologies in the chapter Types of Inventory Reports

Perpetual inventory management challenges

Perpetual inventory management is a far better approach for modern businesses, it does require some set up costs – from barcode scanners, and accounting software to inventory management software.

Why is inventory management important?

Inventory management dictates how you run your business, serve your customers and grow sales. For businesses based around selling products – from craft breweries to big wholesale distributors – managing inventory efficiently is crucial. Here are three key reasons why.

Run your business smoothly

If your business doesn’t manage its inventory properly, it will quickly fall apart.

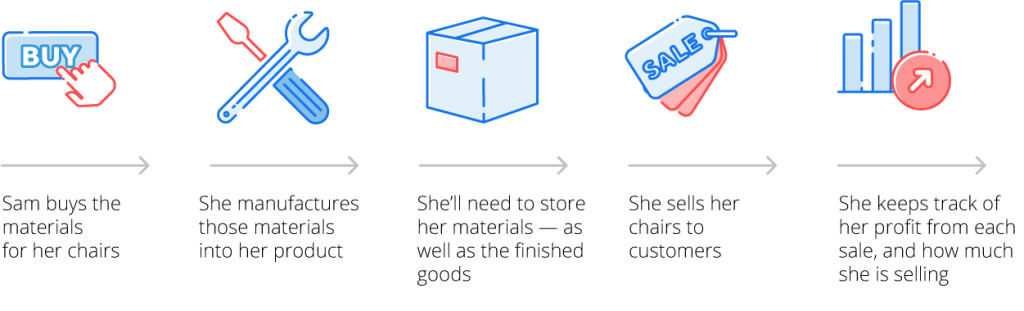

Sam, for instance, needs to match her supply of materials and production to customer demand. If she makes more chairs than she can sell, she’ll need to find somewhere to store the excess: which could end up cutting into her margin. On the other hand, if she runs out of any one of her raw materials, production will cease entirely until she restocks.

Many small businesses rely on manually counting stock to track what’s in store. But stock counts are disruptive and time-consuming, taking time away from making and selling products. So, putting a system in place that doesn’t require stocktakes for accurate figures is imperative.

Find out more:

Keep customers happy

Inventory management dictates:

- How quickly you can get your products to your customers

- How reliably you can fulfil orders

- How much visibility you can give your customers

Customers will be much more likely to come back for more if they know your organisation can consistently deliver orders on time and let them know what’s available. This is especially true when it comes to business-to-business transactions. For a consumer, a missed deadline might mean an inconvenience. For a business, it can mean lost sales and profits.

Find out more:

- Three measures of customer satisfaction

- Five ways that inventory management improves customer satisfaction

Grow your company

As businesses grow in complexity, their inventory management needs get more complex as well. When Sam adds new product lines, hires staff, opens new production facilities and grows her customer base, the organization of materials and stock will get harder.

That makes it important to get control over your physical inventory from day one if you plan on scaling. Rapid growth tends to bring a lot of time consuming tasks: hiring staff, moving to bigger premises and negotiating with new suppliers. So putting an effective stock system in place early is key. The later you leave it, the longer it will take — and you’ll have less time to do it.

Find out more:

But these aren’t the only advantages of inventory management. It can also bring several direct benefits to your business’ bottom line:

- Make it easy to add new products and channels, analyse performance and empower salespeople with up-to-date product information, so you can grow sales revenue

- Eliminate the inefficiencies that lead to lost stock, overstocking, and stockouts — reducing holding costs and growing margins

- Reduce the time and manpower spent on inventory admin, saving on staff costs

Find out more about inventory management strategy here.

How to improve inventory management

1. Focus on your needs

A warehouse full of inventory can be a daunting task. One way of making managing it all easier is to identify the items that are the most important and focus on them first. It’s highly unlikely that every item in your warehouse will have the same demand from customers. Keep the top-selling items in stock, and you’ll have made a great start at keeping your customers happy.

2. Engage with suppliers

In any stock-based business, it is crucial to manage supplier relationships well. Developing constructive relationships with your business’ key suppliers is important to secure reliable supply, unlock competitive pricing and to understand emerging trends that may impact your business.

3. Develop an inventory management system

How your business deals with order quantities, replenishment cycle times, safety stock, forecasts, seasonality and more is important. Tweak each operation according to your specific business — making sure to keep track of what works and what doesn’t. Making a dramatic improvement in one area can be better than a few small improvements across the board.

4. Use real-time data

Information is a powerful tool, but only when it’s accurate and up to date. Real-time data and analytics — from layered inventory tracking right through to forecasting data, automatic ordering and individualised safety stock — can make a real difference to your business. For the most accurate data, consider using perpetual inventory management software, as it is the best way to ensure the information you need is always at your fingertips.

5. Go mobile

Mobile technology has revolutionised inventory management. Barcode scanning, for example, makes receipting and tracking goods far faster — and helps eliminate unnecessary errors. Sales apps, meanwhile, empower salespeople with inventory data on the road. You no longer need to be tethered to a computer in your warehouse. You can keep track of key business processes from home, on holiday, or wherever you are.

6. Develop an inventory management system

Managing your inventory on an ad-hoc basis will only ever get you so far. To really keep on top of your stock, you’ll need an inventory management system. Every company will have its own unique needs, so picking a system that matches your business is important. In the early days of her company, for example, Sam might be able to manage her inventory using spreadsheets. But a global stock-based business like Amazon requires a bespoke, multifaceted solution that caters to the huge number of orders processed every single day.

Inventory management techniques

No matter the size of your business, employing some of these common inventory management techniques can be a great way to take control of your stock. Here are a few to consider:

- Just-in-time (JIT) inventory. JIT involves holding as little stock as possible, negating the costs and risks involved with keeping a large amount of stock on hand.

- ABC inventory analysis. This technique aims to identify the inventory that is earning you profit, by classifying goods into different tiers.

- Dropshipping. Businesses that use dropshipping essentially outsource all aspects of managing stock — with several benefits but a few key drawbacks.

- Bulk shipments. This technique is based on the assumption that buying in bulk is cheaper. The method is great if a business is sure that their products will sell but can pose challenges when demand suddenly changes.

- Backordering. A backorder is when a customer places an order for stock that is not yet available. Learn more about how backordering impacts inventory control.

- Consignment. This technique allows a consignor, usually a wholesaler, to give their goods to a consignee, usually a retailer, without the consignee paying for the goods up front. The consignor still owns the goods, and the consignee pays for the goods only when they actually sell. This sounds great but it also carries major risks.

- Cross-docking. This system virtually eliminates the need to hold inventory. Products are delivered to a warehouse where they are sorted and prepared for shipment immediately. They are usually reloaded into other trucks at the same warehouse and sent out for delivery immediately.

- Cycle counting. This technique involves counting a small amount of inventory on a specific day without doing an entire stocktake. This method helps your business regularly validate accurate inventory levels in your inventory management software.

Learn more about JIT, ABC analysis and dropshipping here.

Inventory management software

Inventory management software captures and controls inventory data, allowing businesses to better manage their stock. Inventory management software platforms typically integrate with accounting software to ensure accurate and efficient inventory accounting within a business, and can work with multiple other software tools, including eCommerce software, Point of Sale software, CRMs and more.

Most modern inventory management software is cloud-based. That is, users purchase a licence to use the software via the internet, and require no new hardware on site.

Inventory management software is sometimes used interchangeably with the term ERP, or Enterprise Resource Planning, which typically refers to much larger software suites that may or may not include inventory management as a module.

ERP is an example of a single-vendor software solution usually designed for larger organisations, as opposed to a best-of-breed software solution more suitable to a wide range of businesses.

- Learn more about single-vendor vs best-of-breed here.

Best inventory management software

The following are some of the most popular inventory management software vendors.

Zoho Inventory

Zoho Inventory bills itself as an inventory platform for small or growing businesses. It’s just one component in the broader Zoho software suite, which also includes modules for marketing, sales, customer support and legal.

The company is based out of the US, and has been around in some form or another since 1996.

Unleashed

Unleashed is an award-winning cloud-based inventory management platform designed for manufacturers, wholesalers, distributors and eCommerce retailers.

Founded in 2009 in New Zealand, Unleashed was one of the first cloud-native inventory management software platforms available. In 2020 it was acquired by UK software house The Access Group and now serves customers in over 80 countries, with offices in the UK, New Zealand and Australia

Cin7

Cin7 is a well-known brand on the global market, focused on helping multi-channel businesses integrate their different platforms. It has two key products, Cin7 Core and Cin7 Omni, tailored to smaller businesses and scaling businesses respectively.

Cin7 was founded in New Zealand in 2012, and has since gone on to establish offices in Australia, the UK and the US.

Odoo Inventory

Odoo is a broad ERP business software suite consisting of many different apps – finance, sales, website design, as well as inventory management It’s an open source package, uncommon among inventory apps, with a focus on ease-of-use.

The company is from Belgium originally, founded in 2005, and is now an international brand.

Netsuite

Netsuite advertises itself as the number one cloud ERP suite, and is used widely across the world. Like most ERP platforms, Netsuite has produced a great many different apps to control essentially every business function, of which inventory management is one.

It’s also one of the older companies in this list, having started as NetLedger in 1998, going public in 2007, and bought out by Oracle Corporation in 2016.

MRPeasy

MRPeasy is a small-business platform, pitching itself specifically for manufacturers with just 10 to 200 employees. As such, simplicity is one of its selling points, with drag-and-drop functionality being one example of its different design choices to competitors.

It was started in 2000, and has offices in Estonia, the UK and US.

Inventory management software features

With many different features advertised by the different inventory software vendors it can be easy to lose track of the core capabilities an inventory platform should provide. The following are some of the most important inventory management software capabilities.

1. Live inventory tracking

This is the number-one requirement of any inventory management system. The software must show you what stock you have and where it is, in real time.

2. Real-time inventory values

Your finance team need to know what your inventory is worth, as well as its purchase and sale price.

3. Reorder points & alerts

An inventory management system should alert you when stock is running low, and allow you to purchase more. Look for software that lets you set and control minimum and maximum stock levels, and calculate ideal levels based on historic data.

- Learn more: Reorder points

4. Stock taking

Annual stock takes are still required, even for those using perpetual inventory management system – and these are made much easier with inventory software. Especially useful is the ability to run rolling stock counts, where part of the stock is checked while the rest of the business functions as normal. Other features include the ability to run stock takes by warehouse, supplier, bin location or product group.

5. Purchase management

Good inventory management software should help you generate purchase orders and accurately, dynamically generating quantity discounts from suppliers where applicable and providing partial receipts if goods are to be received in different shipments.

6. Supplier management

An inventory app should store information on suppliers, including names, contact details, prices, discounts, products and transaction histories.

7. Serial number tracking, batch tracking (or lot tracking) and SKUs

Ensure your software allows for unlimited SKUs (as some may limit you), and can track both batch and serial numbers to help with traceability, aged stock management and after-sales care.

- Learn more: Complete guide to SKUs

8. Analysis and reporting

Good data analysis functionality, and the ability to generate reports, help you make strategic business decisions.

- Learn more: Business intelligence reporting

9. Bill of Materials (BOMs)

Bills of materials are ‘recipes’ used by manufacturers to detail all the components used in an assembled product. Good Bill of Materials functionality aids efficient production planning and purchasing.

- Learn more: Bill of Materials explained

10. Assemblies

Being able to move transform stock records from a set of individual components into an assembled product within the system – with its own SKU – is an essential feature of inventory management software for manufacturers.

11. Barcode scanning

If you can arm your warehouse staff with barcode scanners, and purchase inventory software which enables their use, your team can scan items into the database instantaneously – no manual data entry, which is prone to human error.

Barcode scanners can also improve accuracy during stocktaking.

12. Pick, pack & dispatch

Look for flexibility and control over pick, pack and dispatch functionality, given this is a core warehouse activity. Flexible pick lists, the ability to create partial shipments and support for International Commerce Codes are a few features to consider.

13. Multi-channel support

Modern businesses tend to sell across multiple channels, and inventory software should support this. You must be able to integrate different sales channels into your system to ensure that, no matter where customers purchase from (in-store, online, in-app, social media, etc.), your inventory is automatically updated.

14. Integrations

Inventory management software doesn’t exist in a bubble. It functions best when paired with other software tools, like accounting, CRM, and eCommerce software

15. Data security

Always check the security features of any software vendor before investing, to ensure all the necessary precautions have been taken at their end. Two-factor authentication is ideal.

16. Inventory forecasting

The ability to set future purchasing strategies based off forecasted demand is an advanced feature of some inventory software tools.

- Learn more: Advanced Inventory Manager

Inventory management software costs

Because most inventory software is sold on a per-license basis, its cost will depend on the size and complexity of the business using it. Recent analysis of 70+ vendors has shown that the average per-user licence is USD$175, with an additional $80 per month on top for support. Licences are commonly paid per user, month or annually.

One-off setup costs can range from $789 (for customer onboarding) at the lower end, up to $10,000 – $40,000 (for bespoke third-party consultation fees).

Factors that affect the cost of inventory management software

- The need for optional add-on modules and integrations

- Number of users

- Number of warehouses

- Currency

- Average order volumes

- Level of customer support required

- General business readiness for cloud-based software

For a detailed breakdown on licence fees, onboarding & implementation costs, plus other costs to be aware of, see the cost of inventory management software guide.

- View Unleashed pricing here.

Inventory software integrations

Inventory management software delivers the most value when it’s integrated with other business systems. These are some of the most common systems integrated with inventory software tools.

Accounting integrations

Xero

Xero is one of the world’s leading financial software platforms designed for small or growing businesses. It includes a variety of critical accounting features which have made it a favourite around the world, including invoicing, bank reconciliation, taxes and bills, profit and loss statements, and more.

Connecting Xero with an inventory management platform lets it access stock transactions processed by the inventory system, making for much more effective and efficient accounting.

- Learn more: Xero inventory management

QuickBooks Online (QBO)

QBO is a simple online accounting platform suitable for small or very small businesses which may not have dedicated financial staff. For this reason, its interface has been built to be as easy to understand as possible, allowing even inexperienced users to access accounting tools and take better charge of their business finances.

- Learn more: QuickBooks inventory management

Access Financials

Access Financials is a full-suite accounting platform with a range of advanced features. While it has scalable software plans, it is generally best for more complex organisations needing a tailored, high-volume system to manage their business.

Unleashed is a part of the Access software group, allowing users of both platforms to seamlessly link the two with automatic syncing and a high degree of configurability.

- Learn more: Access Financials inventory management

CRM Integrations

Prospect

Prospect is a stock-aware CRM platform. That means, on top of typical CRM functions like storing, tracking and managing customer information, it also offers functionality such as quoting, ordering, special pricing, back orders, serial number tracking and more.

For any wholesaler, distributor or manufacturer Prospect is a natural CRM choice.

- Learn more: Stock-aware CRM with Prospect

Salesforce

Salesforce is one of the world’s most popular CRM platforms, used by thousands of companies.

Connecting Salesforce to inventory management software lets users keep all of their customer information across the business in one place, and better manage their sales and marketing.

- Learn more: Salesforce inventory management

eCommerce inventory management

Good inventory management is essential for any eCommerce business.

One of the core problems smaller organisations face when selling across channels is the issue of disconnection – where selling on one platform (i.e. in-store) does not update the back-end of another (i.e. online or social media), allowing two customers to buy the same item where only one was on in stock at the time.

A multi-channel inventory management system helps solve this problem by connecting all sales channels into a single dashboard, ensuring real-time inventory visibility – and up-to-date records on all platforms.

Shopify inventory management

Shopify is one of the most popular eCommerce apps on the market thanks to its simplicity and quick setup; users can build their own online store and sell straight to customers remarkably fast, without needing much technical expertise.

The app comes preloaded with basic inventory management features, allowing you to track inventory through your POS system, issue purchase orders, and report on sales trends (so you know not to buy too much stock). But, it’s best-suited for smaller organisations with only one sales channel, and not too many products to sell.

As soon as you sell across multiple channels, manufacture or assemble your own goods, or need expanded feature sets (like serial number tracking), you will likely need to upgrade to a dedicated inventory control app.

Amazon inventory management

Amazon offers some inventory management capabilities to Fulfilment by Amazon (FBA) customers, including the tracking of stock levels, sales, and orders made on international marketplaces. It also has some basic machine learning built-in, to help business owners identify optimum inventory levels.

Sellers not on the FBA programme will need to use their own inventory app, and sellers using FBA may wish to enhance their inventory control features by connecting Amazon with a dedicated inventory platform.

- Learn more: Integrating Unleashed with Amazon

WooCommerce inventory management

WooCommerce is an open-source eCommerce platform that was built for WordPress sites. The idea of the app is that anyone should be able to turn their website into an online store, enhancing the basic functionality already present in-app by adding third-party plug-ins.

Inventory management will need to be one of the plug-ins you install, to ensure you never lose track of your stock. There are a few plug-ins which have been made just for WooCommerce, but of course you can also integrate a dedicated inventory management system to the platform to expand that functionality.

- Learn more: Managing inventory within WooCommerce

B2B eCommerce

B2B sellers need an eCommerce store just as much as any B2C firm.

To start selling online as a B2B business, you don’t need to invest in different apps. If you already use Unleashed for inventory control for example, consider the Unleashed B2B Store for taking on-account sales.

- Learn more: Unleashed B2B Store

API connectors

Inventory management software does not necessarily require a premade plugin to work with an existing system.

Many of the world’s top apps offer custom API connectors for their customers, especially larger organisations, in order to properly integrate the inventory control features of their app with an existing software suite.

- What is an API? An Application Programme Interface is like a software version of a travel adapter. These functions and procedures allow one application to access the data of another, defining how the two systems should interact.

To determine whether or not the inventory control app of your choice will integrate with your systems through a custom API, you will need to get in touch with their support team.

- Learn more: Understanding the Unleashed API

How to grow your inventory management skills

Use the Unleashed Academy video training series to learn more about inventory management and put your knowledge into practice.

Inventory management glossary

Let’s look at some of the basic terminology and formulas you need to know before diving deeper into inventory management systems.

Cost of goods sold

Cost of goods sold (COGS), otherwise known as cost of sales, refers to the direct costs of producing goods. This includes the cost of the materials and labour directly used.

Days inventory outstanding (DIO)

Days Inventory Outstanding, also known as Days Sales of Inventory, is used to measure the average number of days a company holds inventory before selling it.

Economic order quantity (EOQ)

The economic order quantity is the optimal order quantity at any given point in time. An optimal EOQ minimises total holding and ordering costs. It is sometimes known as the optimum lot size.

Finished products

Finished products, or finished goods inventory, refers to the number of manufactured products in stock that are ready to sell.

Inventory accounting

Inventory accounting deals with valuing and accounting for changes in assets. Inventory involves goods in three stages of production: raw goods, in-progress goods, and finished goods. An accurate inventory accounting system keeps track of changes to inventory at all three stages and adjusts asset values and costs accordingly.

Inventory costs

Inventory costs are the costs associated with procuring, storing and managing inventory. They can be categorised into one of three types: ordering costs, carrying costs and shortage costs.

Inventory management software

A software system for tracking inventory levels, orders, sales and deliveries. It can also be used in production to create a bill of materials and other production-related documents.

Lead time

In an inventory management context lead time is the period between an order being placed to replenish inventory and when the order is received.

Point of sale

The point of sale, or point of purchase, is the time and place in which a retail transaction is completed. It usually involves an invoice and options to make payment.

Purchase order

A purchase order is a document created by a buyer and sent to a vendor requesting goods or services. The buyer will, at a minimum, specify what products are being ordered, the quantity, the agreed price, and delivery and payment terms.

Reorder point

This is the level of inventory which triggers an action to replenish it. It is a minimum amount of stock a business needs to have, such that, when stock falls to this amount, the item must be reordered.

Safety stock

This refers to a buffer or reserve of critical stock that is held to protect against unforeseen supply or demand pressures.

Sales channels

A way of bringing products or services to market so that consumers can buy them. Sales channels can be direct if it’s selling directly to consumers, or indirect if an intermediary is involved.

Stock levels

Otherwise known as inventory levels, stock levels are the quantity of goods or raw materials kept on the premises of a business.

Supply chain

A supply chain is a system of organisations, people, activities and resources involved in supplying a product or service to a consumer.

4 inventory management formulas

For new business owners, the following calculations might seem daunting, but don’t let that deter you. These formulas are essential for keeping stock levels optimised. Let’s explore:

- The Economic Order Quantity (EOQ) formula

- The Days Inventory Outstanding (DIO) formula

- The safety stock formula

- The reorder point formula

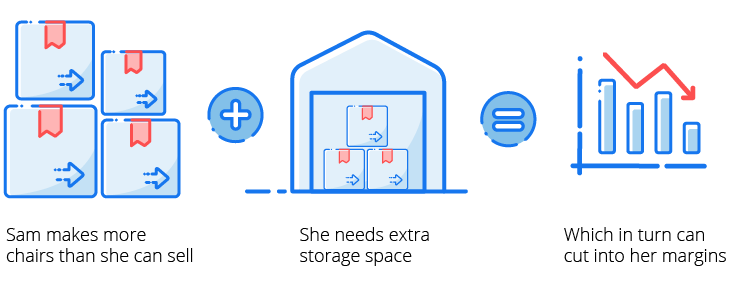

Calculating Economic Order Quantity (EOQ)

It’s important to buy the right amount of inventory stock – neither too little, nor too much. You use the EOQ formula to determine the optimal order quantity – one that minimises the costs of ordering, receiving and holding inventory.

Where:

- D is the setup cost per order; this typically includes shipping and handling costs

- K is the demand rate (your quantity sold per year)

- H is the holding cost per year per unit

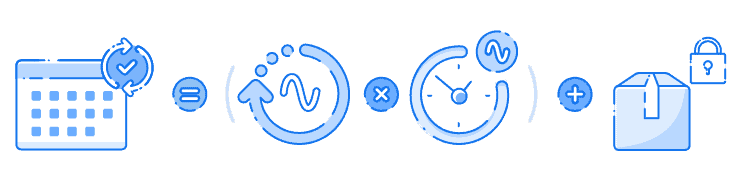

Calculating Days Inventory Outstanding (DIO)

The Days Inventory Outstanding formula goes a step further than the inventory turnover ratio by putting the figure into a daily context and providing a more accurate picture of a company’s inventory management and overall efficiency. Generally a low DIO is preferred but to make sense of it, you need to take into account the industry and market dynamics.

Where:

- Average inventory = (Beginning inventory + Ending inventory) / 2

- COGS is your cost of goods sold

- Days in Period is the number of days in the timeframe that you want to measure, whether it’s weekly, quarterly or annually

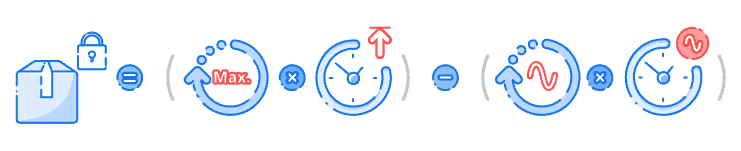

Calculating safety stock

Knowing how much buffer stock to hold will help your business navigate safely through demand and lead time fluctuations. It might seem daunting but all you need to know are your purchase and sales orders history.

Calculating reorder point

You use the reorder point calculation to determine when to reorder stock. Small business owners often rely on intuition and past experience to know when to place another order, but as the business grows, this quickly becomes unsustainable.

What are inventory costs?

Knowing your inventory costs helps you make smarter decisions. There are three broad categories of inventory costs: ordering costs, carrying costs, and shortage costs.

Inventory ordering costs

This is the expense incurred in creating and processing an order to a supplier. You’d use this to determine the EOQ of your inventory. Examples of ordering costs are:

- Cost to prepare a purchase requisition or purchase order

- Cost of the labor required to inspect receipted goods

- Cost to process the supplier invoice related to an order

- Cost to prepare and issue a payment to the supplier

Inventory carrying costs

Carrying costs are the expenses related to storing unsold goods. This includes the tangible costs such as storage, handling, and insuring, as well as intangible costs such as depreciation, the cost of deterioration and obsolescence and opportunity costs. Carrying costs will generally comprise 20% to 30% of a business’ total inventory costs.

Inventory shortage costs

Also known as stock out costs, this is the expense that arises from an out-of-stock situation. This can include measurable costs such as the cost of expedited shipping, buying last minute from another supplier, or loss of the margin on incomplete sales. These also include costs that are hard to quantify such as loss of customer confidence or loss of customers, idle employees and loss in goodwill.

Next steps

Deciding when you might need dedicated inventory management software is a key step in the growth of your company. To find out more about how to manage your inventory better, take a look at our guide to inventory management systems. Or if you’d like more information on the fundamentals of stock, read our inventory management basics blog.

Inventory FAQs

Inventory is the goods that your company handles with the intention of selling. It might be raw materials that you buy and turn into something entirely new, or it might be a bulk product that you break down into its constituent parts and sell separately.

Finished goods/for-sale goods: The products you sell to your customers.

Raw materials: The inventory you use to make your finished goods

Work-in-progress inventory: Essentially, unfinished goods — inventory that is part-way through the manufacturing process

MRO inventory: MRO stands for maintenance, repair and operating. This is the inventory you use to support the manufacturing process

Safety stock: The additional inventory you keep in store to deal with supplier shortages or surges in demand

‘Inventory’ and ‘Stock’ mean slightly different things. Stock generally means finished goods ready for sale, while inventory refers to stock, plus all the other kinds of inventory – especially components, parts or ingredients that go on to become stock.

Start your free 14-day Unleashed trial now. All features included. No credit card needed. Sign up now